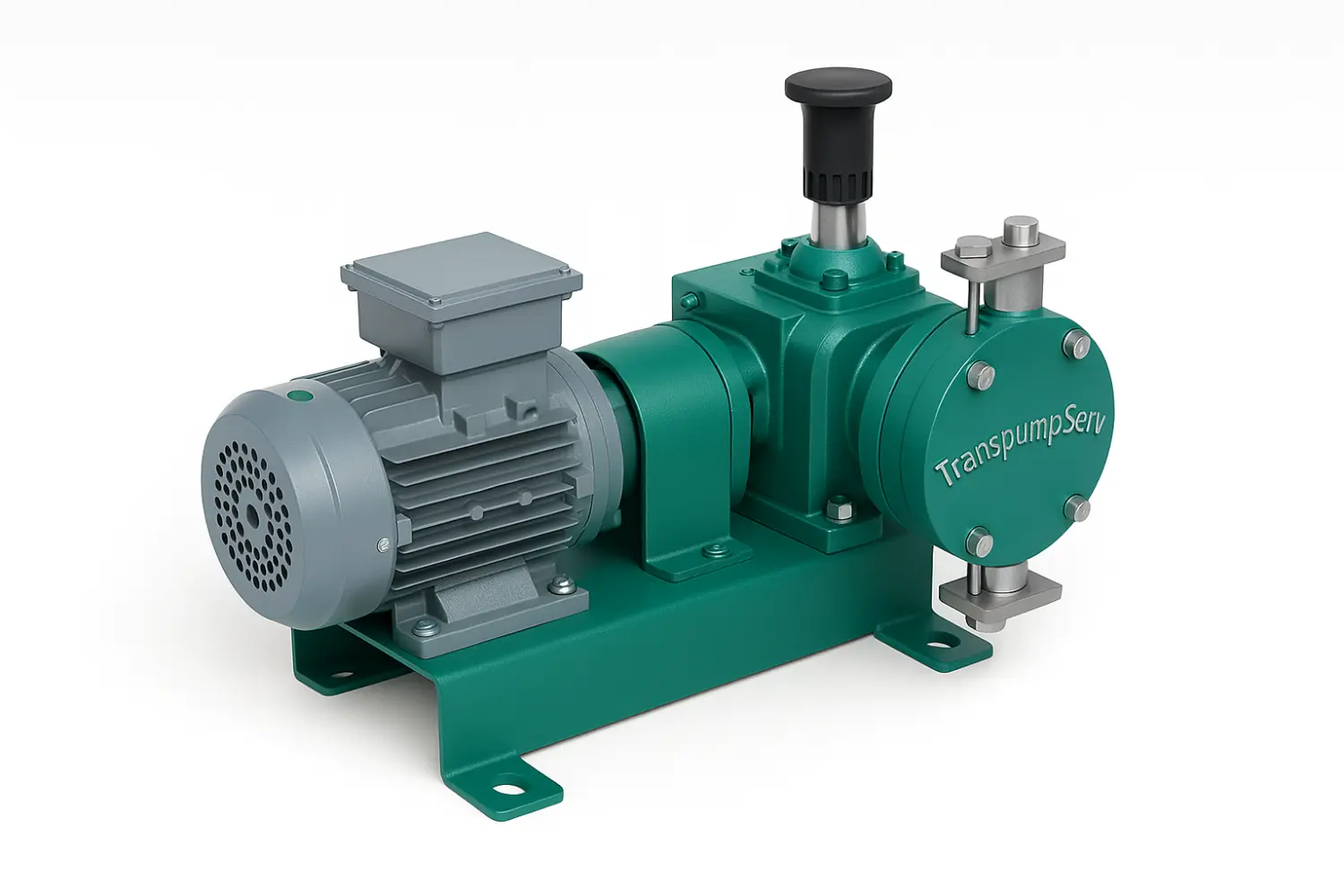

FeedDose (TfeedX)

FeedDose (TfeedX) is a precision-engineered dosing and metering pump designed for accurate and reliable chemical feed applications. Built for consistency, it ensures controlled and repeatable dosing performance, making it ideal for water treatment plants, chemical dosing systems, and pharmaceutical feed processes.

Download CatalogProduct Description

These pumps are available in mechanical diaphragm, hydraulic diaphragm, and plunger

designs, offering flexibility depending on chemical compatibility, dosing accuracy, and system requirements.

Key Design Features

• Precision dosing with repeatability better than ±1%

• Complies with API 675 standards (for process metering applications)

• Available in mechanical diaphragm, hydraulic diaphragm, or plunger type

• Adjustable stroke length and frequency for accurate flow control

• Leak-proof diaphragm options for hazardous chemical dosing

• Modular construction for ease of maintenance

• Compact, skid-mountable design for system integration

Drive & Control Options

• Manual stroke adjustment

• Electric actuator for remote/automatic control

• Variable frequency drive (VFD) integration for flow regulation

• PLC/SCADA compatible electronic control options

• Multi-head configuration for dosing different chemicals simultaneously

Materials of Construction

• Pump Head: PP, PVDF, Stainless Steel 316, Alloy 20

• Diaphragm: PTFE, EPDM, Viton

• Valves: Ceramic, SS316, Hastelloy, PTFE options

Suitable Applications

• Water & Wastewater Treatment – chlorine, alum, lime, coagulant dosing

• Chemical Processing – acids, alkalis, and process additives

• Pharmaceutical & Biotech – precise chemical feed for critical applications

• Power & Energy – boiler chemical dosing, cooling water treatment

• Food & Beverage – controlled additive and preservative dosing

Technical Specifications

| Parameter | Specification |

|---|---|

| Flow Range | 0.5 to 1,000 LPH |

| Discharge Pressure | Up to 10 bar (plunger type up to 400 bar) |

| Accuracy | ±1% of set point |

| Drive Type | Electric motor-driven (optional pneumatic/hydraulic actuation) |

| Temperature Range | Up to 100°C (higher with special materials) |

| Control | Manual, automatic, or electronic (PLC/SCADA integration) |