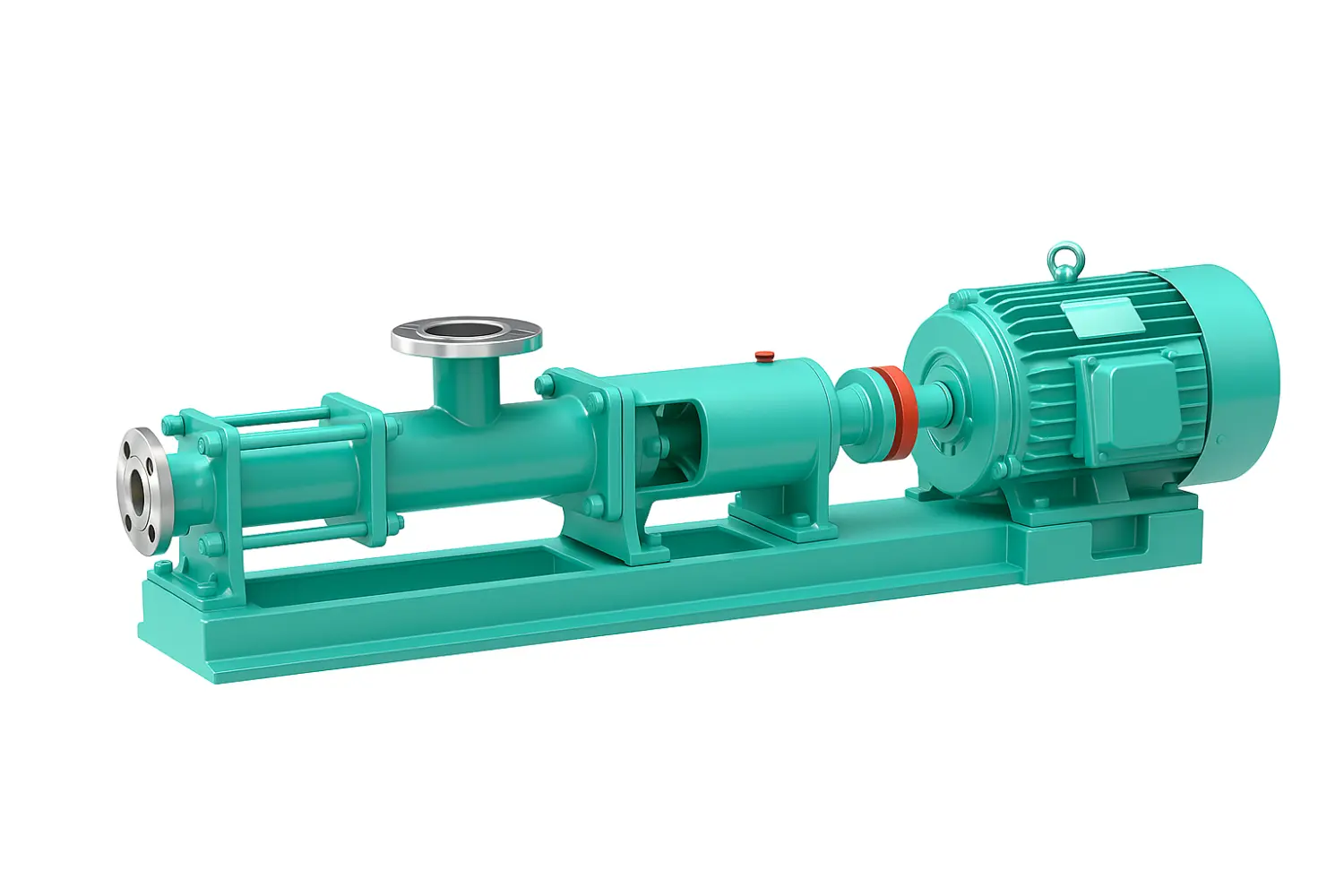

Sludgemax (TsludX)

Sludgemax (TsludX) is a series of progressive cavity screw pumps engineered for reliable pumping of sludge, thick slurries, and dewatered effluent. Designed for continuous, low-pulsation flow, these pumps provide superior handling of viscous, shear-sensitive, and abrasive fluids encountered in sewage treatment plants, effluent plants, and industrial sludge processing.

Download CatalogProduct Description

Sludgemax (TsludX) is a series of progressive cavity screw pumps engineered for reliable

pumping of sludge, thick slurries, and dewatered effluent. Designed for continuous,

low-pulsation flow, these pumps provide superior handling of viscous, shear-sensitive, and

abrasive fluids encountered in sewage treatment plants, effluent plants, and industrial sludge

processing.

The rotor-stator design ensures uniform, gentle conveying without clogging, making it ideal for

sludge transfer and dewatering operations.

Key Design Features

• Progressive cavity / screw pump principle for continuous, low-pulsation flow

• Capable of handling viscous, abrasive, and shear-sensitive fluids

• High solids content handling without clogging

• Modular design with replaceable rotor and stator

• Low operating speed → reduced wear, longer service life

• Self-priming capability with strong suction lift

• Energy-efficient operation for continuous duty

• Option for hopper feed design with bridge breaker for dewatered sludge

Seal and Shaft Technology

• Mechanical seals: single, double, cartridge options

• Gland packing arrangements for abrasive sludges

• Shaft protection sleeves to minimize wear

• Seal flushing and barrier fluid systems for harsh sludge conditions

Bearings and Certifications

• Heavy-duty bearing housing for continuous sludge duty

• Grease or oil bath lubrication depending on service

• ATEX certified for explosive sludge environments

• Complies with API 676 standards (on request)

Suitable Applications

• Sewage Treatment Plants (STP) – raw sludge transfer, digested sludge, dewatered sludge• Effluent Treatment Plants (ETP) – industrial sludge, oily sludge, scum handling

• Effluent Treatment Plants (ETP) – industrial sludge, oily sludge, scum handling

• Dewatering Systems – sludge feed to filter press, centrifuge, belt press

• Dewatering Systems – sludge feed to filter press, centrifuge, belt press

• In

Technical Specifications

| Casing Materials | Cast Iron, Stainless Steel 316, Duplex options |

|---|---|

| Rotor Materials | Stainless Steel, Alloy Steel, Duplex with coatings |

| Stator Materials | Nitrile Rubber, EPDM, Viton, HNBR |

| Max. Capacity | Up to 500 m³/h |

| Max. Pressure | Up to 24 bar (multi-stage) |

| Max. Solids Content | Up to 40% |

| Max. Temperature | Up to 120°C (higher with special elastomers) |

| Speed Range | 200–600 rpm (low speed for longer life) |